The swarmandal is a plucked box zither of Indian origin and used as an accompanying instrument for the vocal classical music of Northern India. Modern swarmandals are similar to western zithers in shape and construction. In fact, autoharps with the chord bars removed are sometimes used as an equivalent instrument in India today.

The swarmandal is a plucked box zither of Indian origin and used as an accompanying instrument for the vocal classical music of Northern India. Modern swarmandals are similar to western zithers in shape and construction. In fact, autoharps with the chord bars removed are sometimes used as an equivalent instrument in India today.

These past few months I have been working with Purnash, a popular musician and multi-instrumentalist who performs in venues across Asia, the subcontinent, and beyond. We have combined our ideas to reinvent the swarmandal and build a hybrid that he has named “Raagaharp”. Raagaharp has a diatonic tuning schedule in the key of Eb for for his vocal range, and a combination of specially constructed lock bars for the deletion of specific notes within the immense variety of ragas he performs.

I am only familiar with western musical concepts as they apply to folk and old time music. I cannot understand or explain ragas. They are described as improvisations on a construct of modes, scales, and notes, each to affect the emotions of the listener…. and there are hundreds of them!

The strings are played open. According to the musician, for a given raga he will mute some notes and re-tune some strings. He does this on-the-fly (imagine doing this between autoharp tunes!). To change the instrument’s setup between ragas, we arrived at the idea of a combination of fine tuners and lock bars.

The strings are played open. According to the musician, for a given raga he will mute some notes and re-tune some strings. He does this on-the-fly (imagine doing this between autoharp tunes!). To change the instrument’s setup between ragas, we arrived at the idea of a combination of fine tuners and lock bars.

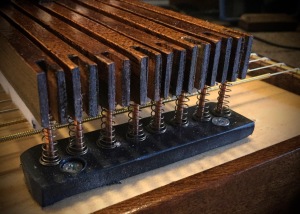

The lock bars of an autoharp function much like their adjoining chord bars… held aloft by springs when not in use and locked down by some sort of a wedge. The swarmandal’s lock bars will be swapped in and out as needed and seated, without springs, against the strings by a magnetic cover.

The lock bars of an autoharp function much like their adjoining chord bars… held aloft by springs when not in use and locked down by some sort of a wedge. The swarmandal’s lock bars will be swapped in and out as needed and seated, without springs, against the strings by a magnetic cover.

The fixture can hold one or two bars at once and also serves as a hand rest. Inlaid in the underside of the cover are two strong magnets for attachment. The cover is easily removed and replaced for changing out the bars.

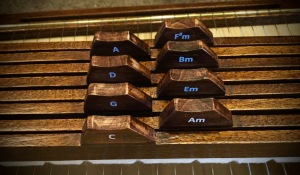

The bars are made of curly maple and felted in combinations of single and double notes. There are only seven notes in the scale but only six different notes will be muted since the keynote, Eb, will always be open. Six different bars are sufficient but I made an additional six bars with double notes.

The bars are made of curly maple and felted in combinations of single and double notes. There are only seven notes in the scale but only six different notes will be muted since the keynote, Eb, will always be open. Six different bars are sufficient but I made an additional six bars with double notes.

Autoharp chord/lock bars reside on the ‘harp and are seldom removed unless they need attention. The swarmandal’s lock bars will be constantly swapped in and out. To protect the fragile felt blocks I made a case to house the twelve+ bars and included extra felt for future wear.

Autoharp chord/lock bars reside on the ‘harp and are seldom removed unless they need attention. The swarmandal’s lock bars will be constantly swapped in and out. To protect the fragile felt blocks I made a case to house the twelve+ bars and included extra felt for future wear.

I included my usual tuning strip/duster that can be temporarily inserted underneath the strings as a guide for tuning. The strings are mostly in pairs and tuned to only seven notes. The notes are labeled on the strip and lock bars according to the Indian Solfeggio system….

I included my usual tuning strip/duster that can be temporarily inserted underneath the strings as a guide for tuning. The strings are mostly in pairs and tuned to only seven notes. The notes are labeled on the strip and lock bars according to the Indian Solfeggio system….

Eb is S F is R G is G Ab is M Bb is P C is D D is N

I address musical notes as sharps and naturals from A to G. The completion of this task required some careful translation. For example, a note like Eb to me is D# but on the tuning strip it appears as S.

The musician finds the sound of most swarmandals to be unpleasant and for his custom instrument he requested a warmer, less brilliant sound, particularly in the treble area. I tried to accomplish this with an African mahogany soundboard and by using Delrin rod for the bridge caps. Delrin is a hard plastic material that will render less sustain than the harder brass rod that I usually use.

At his request, I applied a matte lacquer finish over a specially formulated Benjamin Moore color called “Hale Navy”. This color seems to appear blue under some lighting and black under others. Obtaining this color in spray form was pricey but the attractive appearance is worth the excessive cost.

I admit, there is little difference between this Indian zither and the autoharps that I have been building over the years. Creating this instrument and listening to Indian music has been a wonderful exposure to Eastern musical culture enabled by an amazing musician and new friend.

Along the way I have made a couple of improvements on my “Child ‘Harps”. I had been making slotted chord bar holders by cutting down the manufactured plastic holders once produced by Oscar Schmidt. These work well but are a bit noisy when the wooden bars “clack” against the hard plastic. My newer Child ‘Harps now have the quieter Delrin and steel pin combs as on my standard sized autoharps.

Along the way I have made a couple of improvements on my “Child ‘Harps”. I had been making slotted chord bar holders by cutting down the manufactured plastic holders once produced by Oscar Schmidt. These work well but are a bit noisy when the wooden bars “clack” against the hard plastic. My newer Child ‘Harps now have the quieter Delrin and steel pin combs as on my standard sized autoharps. Child ‘Harps have carried seven chords in two rows. I now offer eight chords. Here is the G/D diatonic version.

Child ‘Harps have carried seven chords in two rows. I now offer eight chords. Here is the G/D diatonic version. As with the Child ‘Harps’ larger siblings, laser cut sound hole rosettes are popular. there is a variety of styles available in this smaller size for this smaller autoharp.

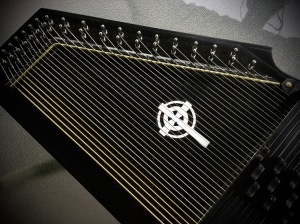

As with the Child ‘Harps’ larger siblings, laser cut sound hole rosettes are popular. there is a variety of styles available in this smaller size for this smaller autoharp. A more recent build is this thirty-six string, fifteen chord chromatic I built for a gentleman just beginning his autoharp journey. His preferences included a Celtic cross sound hole rosette, an all black finish, and a salvaged OS tuning label at the anchor end.

A more recent build is this thirty-six string, fifteen chord chromatic I built for a gentleman just beginning his autoharp journey. His preferences included a Celtic cross sound hole rosette, an all black finish, and a salvaged OS tuning label at the anchor end.

This instrument resembles the old black model A autoharps of the past but features all of my modern improvements for tone, volume, stability, and play ability.

This instrument resembles the old black model A autoharps of the past but features all of my modern improvements for tone, volume, stability, and play ability. Apertures (sound holes) in stringed musical instruments have been studied, experimented with, and designed for a variety of acoustic functions and characteristics. While a sound hole’s size, shape, and position certainly influence tone and volume, its appearance is what catches the eye and creates a kind of identity.

Apertures (sound holes) in stringed musical instruments have been studied, experimented with, and designed for a variety of acoustic functions and characteristics. While a sound hole’s size, shape, and position certainly influence tone and volume, its appearance is what catches the eye and creates a kind of identity.

This thirty-seven string, fifteen chord diatonic autoharp plays in the keys of G and D. The Sitka spruce soundboard features a weeping heart sound hole and curly maple bridges. Walnut trims the sides, chord bar buttons, and tailpiece.

This thirty-seven string, fifteen chord diatonic autoharp plays in the keys of G and D. The Sitka spruce soundboard features a weeping heart sound hole and curly maple bridges. Walnut trims the sides, chord bar buttons, and tailpiece. The fifteen maple chord bars are arranged in a custom, three row layout.

The fifteen maple chord bars are arranged in a custom, three row layout. Added options are Daigle fine tuners and a Schreiber electromagnetic pickup.

Added options are Daigle fine tuners and a Schreiber electromagnetic pickup.

A musician from Tennessee recently commissioned this custom autoharp with several features that, to me, are very similar to the fifteen chord Oscar Schmidt and ChromaHarp models of the past. Over the years those A style chromatic models with their round sound holes, fifteen chord bars in two rows, and laminated soundboards underwent many improvements by their manufacturers. This musician seems to favor that style of instrument and was able to specify several construction, setup, and cosmetic improvements to suit his preferences and playing style.

A musician from Tennessee recently commissioned this custom autoharp with several features that, to me, are very similar to the fifteen chord Oscar Schmidt and ChromaHarp models of the past. Over the years those A style chromatic models with their round sound holes, fifteen chord bars in two rows, and laminated soundboards underwent many improvements by their manufacturers. This musician seems to favor that style of instrument and was able to specify several construction, setup, and cosmetic improvements to suit his preferences and playing style. Most of my builds have been set up for playing in the area above the chord bars with the high treble strings unobstructed by the chord bar covers. This chord set is positioned closer to the tuning pins to permit play below the chord bars at the anchor end. Many of the old OS A models were arranged this way until playing the instrument upright became common and the bar set was moved south by their owners or the factories. This instrument is designed to be played on the musician’s lap with the left hand at the chords and the right hand playing near the anchor bridge.

Most of my builds have been set up for playing in the area above the chord bars with the high treble strings unobstructed by the chord bar covers. This chord set is positioned closer to the tuning pins to permit play below the chord bars at the anchor end. Many of the old OS A models were arranged this way until playing the instrument upright became common and the bar set was moved south by their owners or the factories. This instrument is designed to be played on the musician’s lap with the left hand at the chords and the right hand playing near the anchor bridge. The old A models chord bars and buttons were 5/16 inches wide. I reduced these bars to a 1/4 inch width to narrow the array while leaving the buttons wide enough as to not require caps. The maple buttons are of a similar style to the older fifteen chord ‘harps and the chords are selected and arranged to the musician’s preference. He prefers a higher action (the height of the felt above the strings) for more vigorous chording. I set the travel high as requested but included extra self-sticking felt strips for under the covers should he choose to adjust the bars lower.

The old A models chord bars and buttons were 5/16 inches wide. I reduced these bars to a 1/4 inch width to narrow the array while leaving the buttons wide enough as to not require caps. The maple buttons are of a similar style to the older fifteen chord ‘harps and the chords are selected and arranged to the musician’s preference. He prefers a higher action (the height of the felt above the strings) for more vigorous chording. I set the travel high as requested but included extra self-sticking felt strips for under the covers should he choose to adjust the bars lower. The modern improvements in the construction of this instrument include a solid spruce soundboard with tuned bracing, a one piece laminated frame, and quiet chord bars mounted on Delrin and steel pin combs. The chord bars, covers, side veneer, bridges, and tailpiece are made of African mahogany that has been stained dark brown. The musician requested that I not apply note labels under the tuning pins so I included a wooden tuning strip/duster that can be positioned under the strings to aid tuning.

The modern improvements in the construction of this instrument include a solid spruce soundboard with tuned bracing, a one piece laminated frame, and quiet chord bars mounted on Delrin and steel pin combs. The chord bars, covers, side veneer, bridges, and tailpiece are made of African mahogany that has been stained dark brown. The musician requested that I not apply note labels under the tuning pins so I included a wooden tuning strip/duster that can be positioned under the strings to aid tuning. A custom built autoharp such as this can be built with the preferred features and options that improve playability and appearance. Sometimes it comes with a surprise: as the owner noted, “I was in shock at how light it is!”.

A custom built autoharp such as this can be built with the preferred features and options that improve playability and appearance. Sometimes it comes with a surprise: as the owner noted, “I was in shock at how light it is!”. I have recently located a source of laser cut ornaments in a variety of subjects. Most are too large to inlay as a sound hole rosette but with many of them, I can trim away the bordering areas for a good fit.

I have recently located a source of laser cut ornaments in a variety of subjects. Most are too large to inlay as a sound hole rosette but with many of them, I can trim away the bordering areas for a good fit. Here is a new custom thirty-six string chromatic autoharp. My standard, one piece pinblock frame features a spruce sound board, laminate back, and 3/16 inch thick walnut veneered sides. Matching walnut was also used for the brass rod-capped bridges, tail piece, chord bar covers, bridges and chord bar covers.

Here is a new custom thirty-six string chromatic autoharp. My standard, one piece pinblock frame features a spruce sound board, laminate back, and 3/16 inch thick walnut veneered sides. Matching walnut was also used for the brass rod-capped bridges, tail piece, chord bar covers, bridges and chord bar covers. The fifteen chord bars are made of curly maple. The contrasting buttons are capped with walnut.

The fifteen chord bars are made of curly maple. The contrasting buttons are capped with walnut.

As a landlocked luthier here in Ohio, I truly miss the ocean. Marsha and I have lived in a coastal town on the Great Barrier Reef. We have wandered beaches in Florida, Cape Cod, Oregon, Nova Scotia, Iceland, and Ireland. We even spent two months at sea working on a container ship that crossed both Tropics and the Equator. With only some photos and a smattering of shells to sustain our fading memories, I sometimes regret leaving those experiences behind for life in the flatlands.

As a landlocked luthier here in Ohio, I truly miss the ocean. Marsha and I have lived in a coastal town on the Great Barrier Reef. We have wandered beaches in Florida, Cape Cod, Oregon, Nova Scotia, Iceland, and Ireland. We even spent two months at sea working on a container ship that crossed both Tropics and the Equator. With only some photos and a smattering of shells to sustain our fading memories, I sometimes regret leaving those experiences behind for life in the flatlands. This thirty-seven string instrument has twelve chord bars shaped like waves. The three rows of buttons resemble white caps. Bridges, chord bar holders, tail cover, and side trim are made of curly maple dyed bright blue to show an iridescent, wave like grain.

This thirty-seven string instrument has twelve chord bars shaped like waves. The three rows of buttons resemble white caps. Bridges, chord bar holders, tail cover, and side trim are made of curly maple dyed bright blue to show an iridescent, wave like grain. A laser cut rosette adorns the sound hole and bare footprints cross the sandy colored solid spruce soundboard.

A laser cut rosette adorns the sound hole and bare footprints cross the sandy colored solid spruce soundboard. The laminated back has been painted bright blue using netting as a stencil. Captured in this fish net is a colorful jellyfish soundhole.

The laminated back has been painted bright blue using netting as a stencil. Captured in this fish net is a colorful jellyfish soundhole.

Recently, a musician from Louisiana sent me an “Old Black Box”, or rather, a thirty-six string, twelve chord Oscar Schmidt autoharp that was manufactured in 1958. As with many of these older “A” models purchased on-line, from families, or from estate sales, it was covered with dust and gunk. Still, it had possibilities so the owner had it polished and restrung with Schreiber “Old Model A” strings. It was sent to me in excellent condition for a couple of useful upgrades.

Recently, a musician from Louisiana sent me an “Old Black Box”, or rather, a thirty-six string, twelve chord Oscar Schmidt autoharp that was manufactured in 1958. As with many of these older “A” models purchased on-line, from families, or from estate sales, it was covered with dust and gunk. Still, it had possibilities so the owner had it polished and restrung with Schreiber “Old Model A” strings. It was sent to me in excellent condition for a couple of useful upgrades. The owner learned to play the old way, below the chord bars. He also wanted to be able to play above the bars in the high treble area. To accomplish this I made chord bars 3/16 inches wide which made the chord set narrower. By repositioning the set in the center, there was now 1-1/2 inches above and 1-1/2 inches below the chord bars allowing play both ways.

The owner learned to play the old way, below the chord bars. He also wanted to be able to play above the bars in the high treble area. To accomplish this I made chord bars 3/16 inches wide which made the chord set narrower. By repositioning the set in the center, there was now 1-1/2 inches above and 1-1/2 inches below the chord bars allowing play both ways. I tried to retain the aged/historical appearance by coloring the new chord bars and holders black and installing a used tuning pin to match the old ones.

I tried to retain the aged/historical appearance by coloring the new chord bars and holders black and installing a used tuning pin to match the old ones. Here is a new custom thirty-seven string chromatic autoharp that I built for a beginning autoharp musician here in Ohio. She plans to play worship and folk music to accompany herself and other vocalists. Because she resides within easy driving distance to Darke County, she and her husband could visit, view the many features and options available, and order the special instrument that is to be a birthday gift from her family.

Here is a new custom thirty-seven string chromatic autoharp that I built for a beginning autoharp musician here in Ohio. She plans to play worship and folk music to accompany herself and other vocalists. Because she resides within easy driving distance to Darke County, she and her husband could visit, view the many features and options available, and order the special instrument that is to be a birthday gift from her family. I always try to make each of my instruments unique so that my clients have a special instrument unlike any other. Of course there are constraints like scale, setup, and structure, but I like to give folks choices. This musician chose a western red cedar soundboard, maple chord bars, and curly cherry for the bridges, bar holders, buttons, and side trim.

I always try to make each of my instruments unique so that my clients have a special instrument unlike any other. Of course there are constraints like scale, setup, and structure, but I like to give folks choices. This musician chose a western red cedar soundboard, maple chord bars, and curly cherry for the bridges, bar holders, buttons, and side trim.

A weeping heart was chosen for the sound hole. I made this by inlaying a 1/8″ thick cherry heart shape into the 1/4″ thick soundboard and then removing the inner heart shape leaving a 1/8″ wide cherry border.

A weeping heart was chosen for the sound hole. I made this by inlaying a 1/8″ thick cherry heart shape into the 1/4″ thick soundboard and then removing the inner heart shape leaving a 1/8″ wide cherry border.

The fifteen maple chord bars feature cherry buttons with the lateral dishing (rather than longitudinal dishing) preferred by the player. They move on #6 steel pins set into Delrin bases. The chord felt is yet uncut pending the player’s preferences.

The fifteen maple chord bars feature cherry buttons with the lateral dishing (rather than longitudinal dishing) preferred by the player. They move on #6 steel pins set into Delrin bases. The chord felt is yet uncut pending the player’s preferences. Structurally, this A style autoharp is built with a one piece laminated pinblock frame and a 1/4″ thick laminated birch back. Lately, I have been routing away unnecessary areas inside the frame to increase the interior volume. This, along with some tuned bracing, improves tone and volume.

Structurally, this A style autoharp is built with a one piece laminated pinblock frame and a 1/4″ thick laminated birch back. Lately, I have been routing away unnecessary areas inside the frame to increase the interior volume. This, along with some tuned bracing, improves tone and volume. Hex screws are components of autoharp fine tuners. They are adjusted with some form of a hex key that is usually supplied with the assembly. This necessary implement is usually stored in the case, pick bag, or somewhere in that room you just walked into but forgot why.

Hex screws are components of autoharp fine tuners. They are adjusted with some form of a hex key that is usually supplied with the assembly. This necessary implement is usually stored in the case, pick bag, or somewhere in that room you just walked into but forgot why.

…………..where it’s right at hand for quick tuning touch ups.

…………..where it’s right at hand for quick tuning touch ups.

Many autoharps, especially manufactured ones, have decals, stickers, or note labels to designate the pitch of each string. These are unsightly and mostly unnecessary once the autoharp has attained a stable tuning. Some musicians convert their instruments to an alternative tuning such as a diatonic setup with a completely different tuning schedule that is no longer supported by the existing labels.

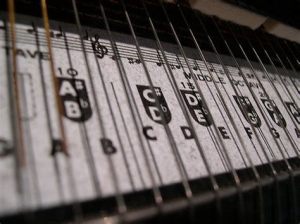

Many autoharps, especially manufactured ones, have decals, stickers, or note labels to designate the pitch of each string. These are unsightly and mostly unnecessary once the autoharp has attained a stable tuning. Some musicians convert their instruments to an alternative tuning such as a diatonic setup with a completely different tuning schedule that is no longer supported by the existing labels. I printed a tuning chart that I glued to a thin strip of wood. This can be slipped under the strings when needed as a reference for tuning each string.

I printed a tuning chart that I glued to a thin strip of wood. This can be slipped under the strings when needed as a reference for tuning each string. On the reverse side of the tuning strip is red felt. It prevents the wooden strip from scratching the soundboard and doubles as a convenient tool to remove dust under the strings.

On the reverse side of the tuning strip is red felt. It prevents the wooden strip from scratching the soundboard and doubles as a convenient tool to remove dust under the strings.

You must be logged in to post a comment.